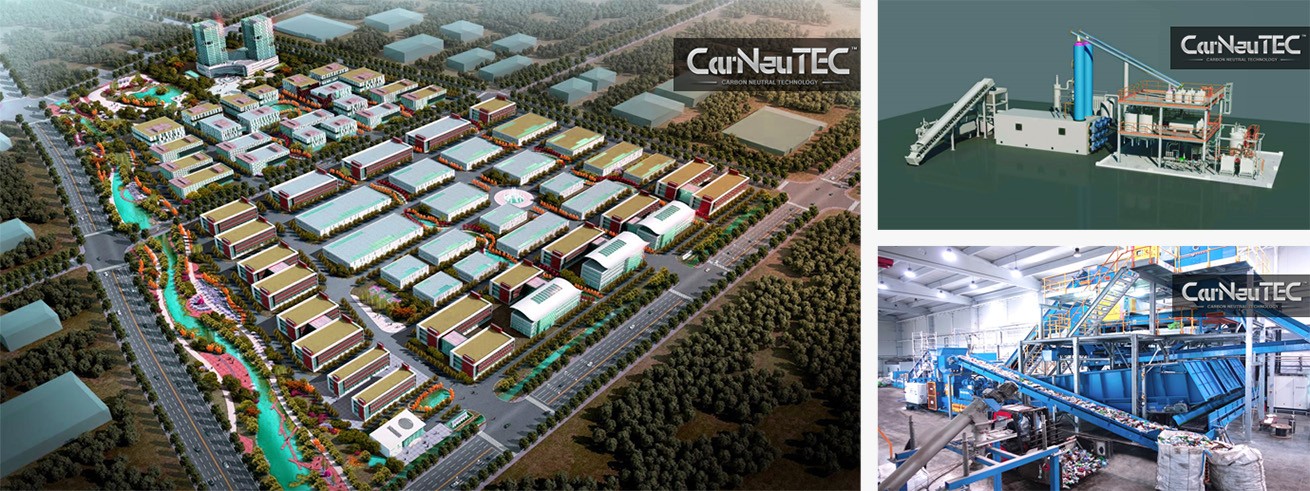

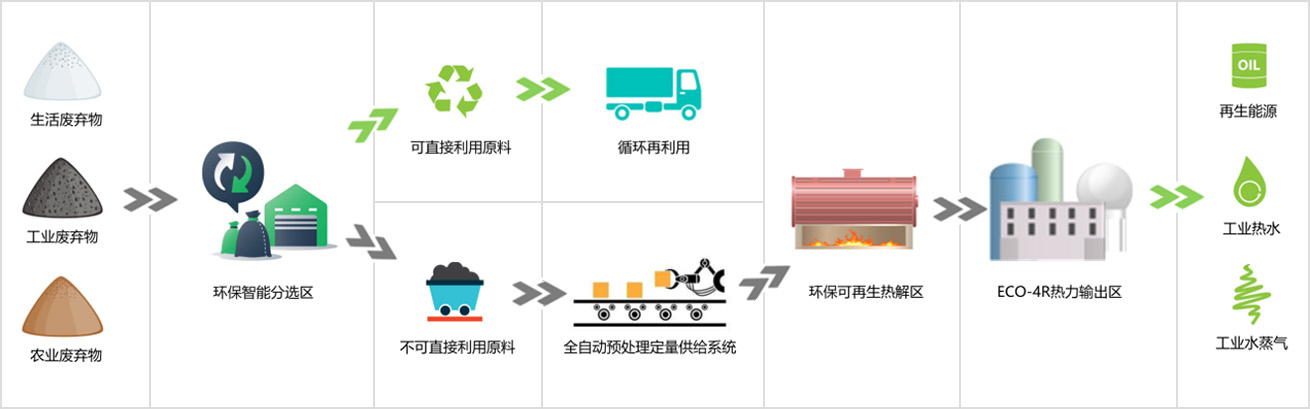

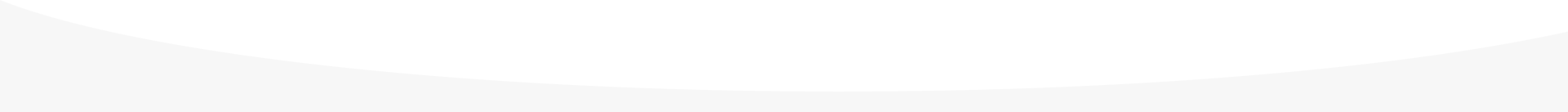

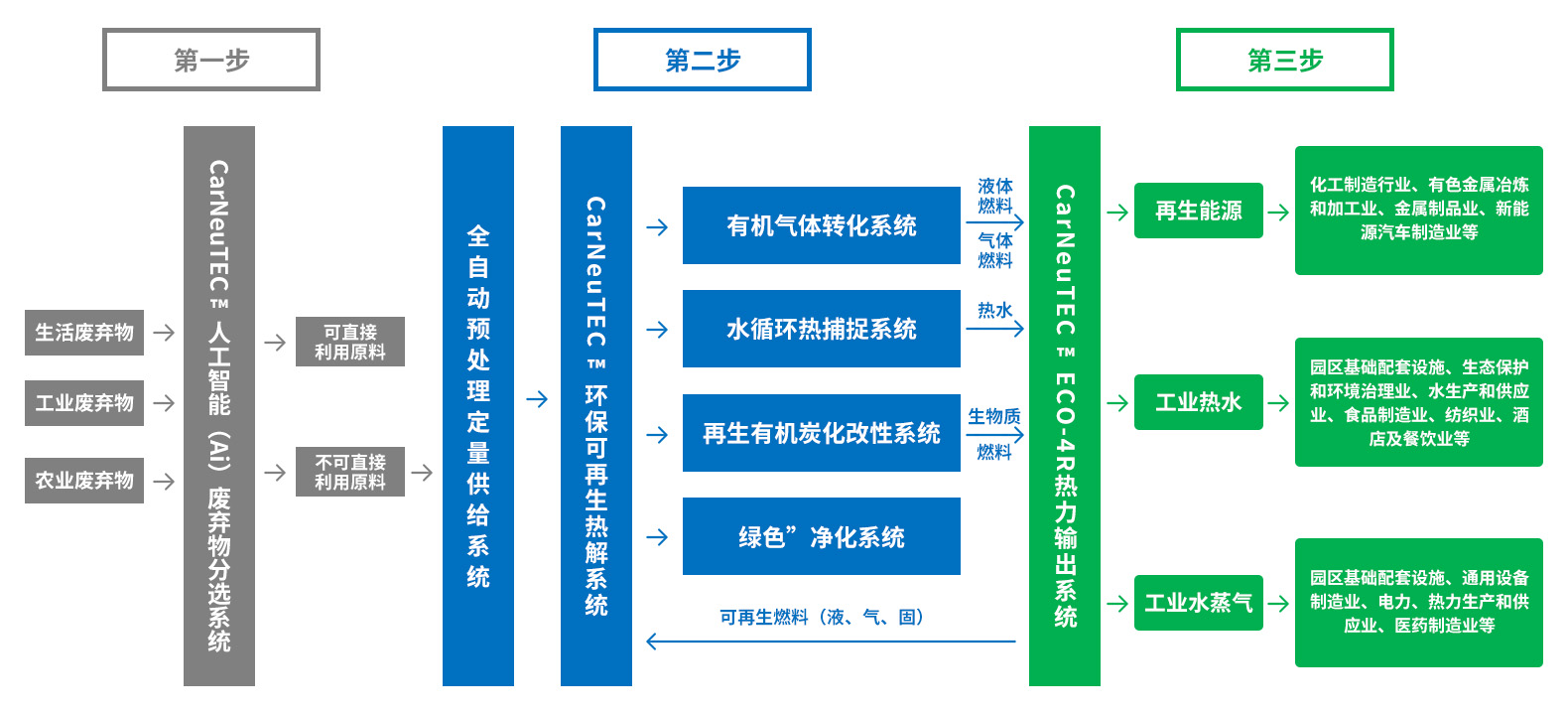

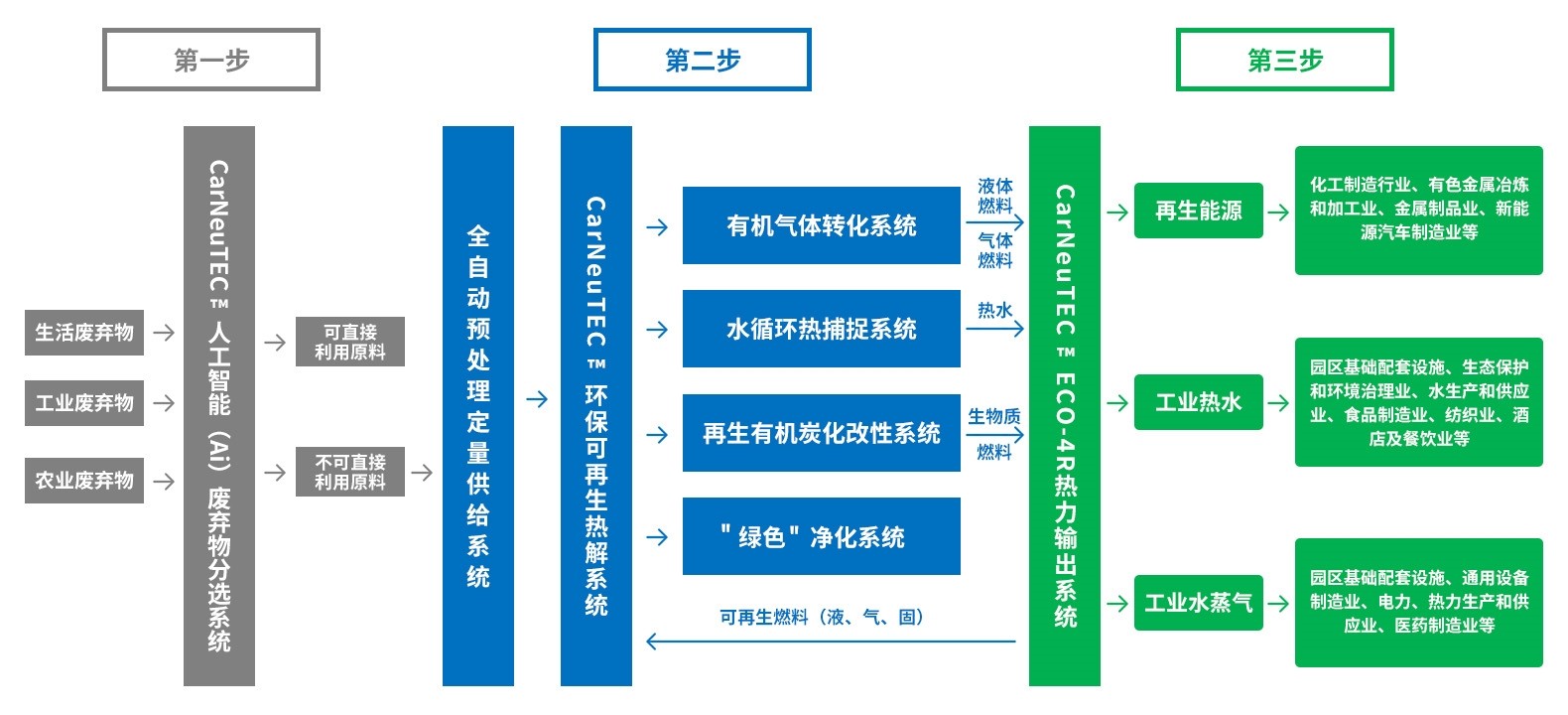

"Carneutec ™ "Environmental protection intelligent carbon reduction center", independently developed by China Huanan international, and based on the technology of "American dur Chemical Research Institute", the project includes three intelligent systems: "environmental protection intelligent separation area", "environmental protection renewable pyrolysis area" and "eco-4r thermal output area". The "environmental protection intelligent sorting area" is a fully automatic intelligent AI identification and sorting area, which can intelligently sort waste rubber and plastic products into raw materials that can not be used directly or directly. "Environmental friendly and renewable pyrolysis zone" carries out precise temperature control and deep pyrolysis treatment on the sorted raw materials that cannot be directly used, and separates liquid fuel, gas fuel, steel wire and biomass fuel. "Eco-4r thermal output zone" carries out physical conversion of liquid fuel, gas fuel, hot water and biomass fuel, and finally generates renewable energy, industrial hot water and industrial steam based on liquid fuel, biomass fuel and gas fuel. It can serve many industries such as energy, metallurgy, papermaking, manufacturing, textile, chemical industry, building materials and food, and broaden the field of renewable resource utilization, Truly realize the closed loop of carbon neutral related industrial chain.

The project is based on the technology of "Dole Research Institute of chemical industry" in the United States. Through the pyrolysis process including fixed bed pyrolysis, moving bed pyrolysis, fluidized bed pyrolysis, rotating (internal rotating) bed pyrolysis and other technologies, the project can achieve high production efficiency, intelligent control, safety and reliability, energy conservation and emission reduction, including three intelligent systems: "environmental protection intelligent separation area", "environmental protection renewable pyrolysis area" and "eco-4r thermal output area".

"Environmental protection intelligent sorting area" sorts waste rubber and plastic products into non directly usable raw materials and directly usable raw materials.

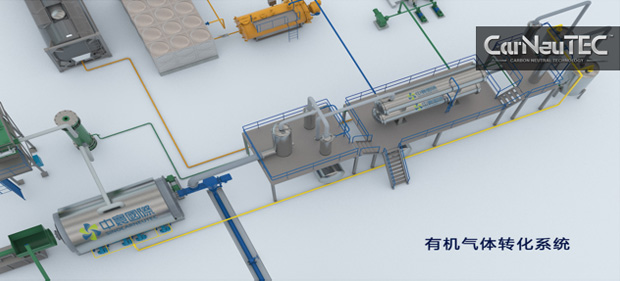

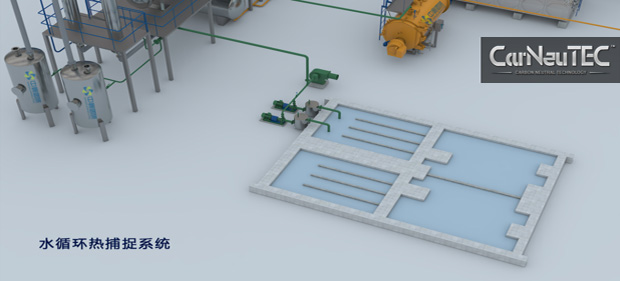

The "environmentally friendly and renewable pyrolysis zone" carries out precise temperature control and deep pyrolysis treatment on the sorted raw materials that cannot be directly used to separate liquid fuel, gas fuel, steel wire and biomass fuel.

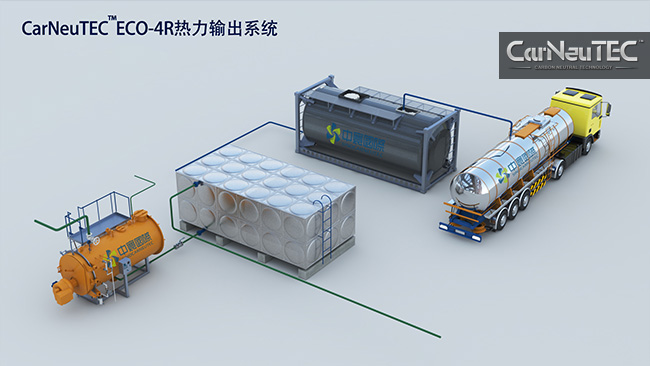

Eco-4r thermal output area "physically converts liquid fuel, gas fuel, hot water and biomass fuel, and finally generates renewable energy, industrial hot water and industrial steam based on liquid fuel, biomass fuel and gas fuel,

Contact Us

Contact number

0411-81821250