Dalian Yishun Green Technology Co., Ltd (Yishun), a subsidiary of Zhonghuan International, has started the construction of the project of comprehensive utilization of 20,000 tons of aluminum ash per year in Binzhou, Shandong Province, and the project of comprehensive utilization of 10,000 tons of aluminum ash per year in Yingtan, Jiangxi Province, in 2023, which is aimed at optimizing and upgrading the plasma disposal technology once again.

Independent research and development strength

On the self-developed solid waste plasma melting harmless treatment technology, Eshun has invested more than 10 million yuan in technology research and development over the past three years, set up a DC plasma solid waste resource utilization pilot base, constructed the first full-process, multi-functional, high-power DC plasma solid waste resource utilization complete set of system pilot equipment, and the capacity of plasma melting furnace product design and manufacturing capacity has reached from 50kVA to 5000kVA. The capacity of plasma melting furnace has reached from 50kVA to 5000kVA, and has beenrecognized as Liaoning Province Specialized, Specialized and New Small andMedium-sized Enterprises (SMEs), Liaoning Province Antelope Enterprises (GazelleEnterprises) and Innovative SMEs.

The company mainly focuses on the harmless and resourceful disposal of industrial aluminum ash, incineration fly ash and residue, precious metal extraction from waste circuit boards, highly toxic wastes, oil sludge sludge, industrial organic salts, metal recycling of waste catalysts, medical waste, metal smelting slag and other fields.

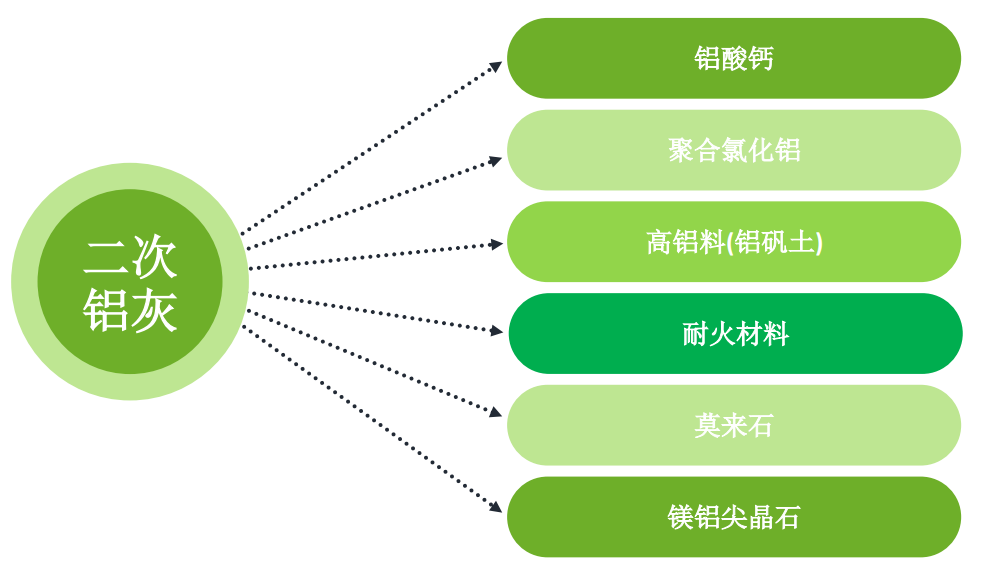

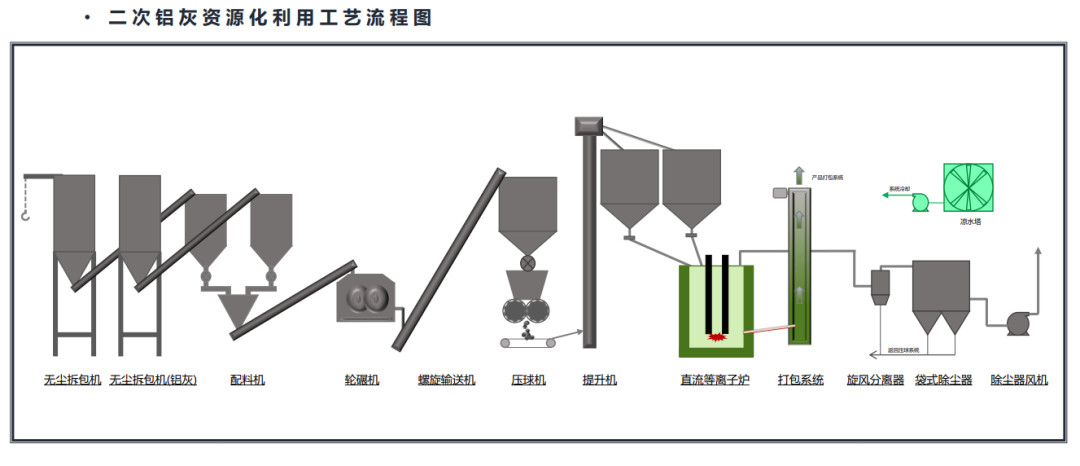

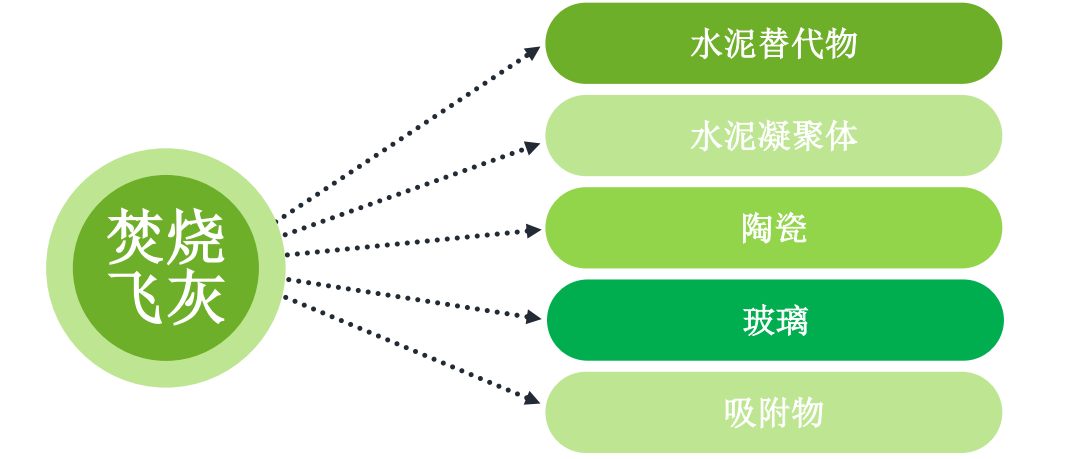

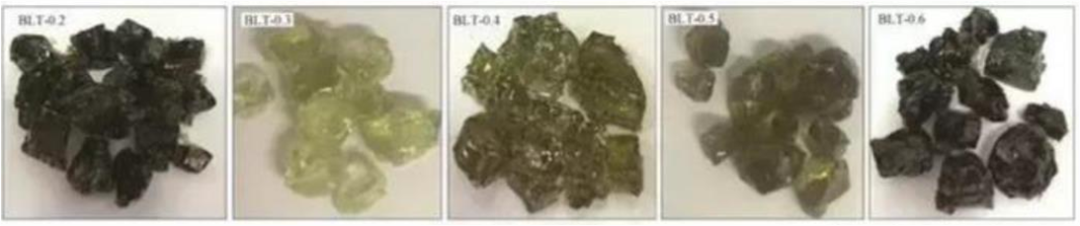

After years of deep plowing in the hazardous waste disposal industry, thecompany's ability to resource utilization is currently in the top three in the country,a number of head of the private equity funds and angel investors have entered thefield of research, 2022 has completed the first round of large private equity funds to increase the capital and expansion of the company's plans for the future in the Beijing Stock Exchange or Shenzhen Stock Exchange to complete the IPO listing. Technology Upgrade Leading Edge The secondary aluminum ash disposal project in Binzhou, Shandong Province, which has already landed, adopts an upgraded version of the process, which can be processed into pre-melted calcium aluminate after disposal, forming a comprehensive utilization of resources, which is more advantageous than the traditional wet process, acid process and pyrotechnic process, and the direction of the resourceization of the subsequent finished products is more expansive. The output value of annual disposal volume of 10,000 tons after technological upgrading is about 40 million yuan, and the energy and electricity consumption is reduced from 1,200°/ton to 800°/ton, which significantly reduces the cost and greatly improves the customer's benefit from resource utilization. Advantages of Plasma Disposal of Secondary Aluminum Ash Technical Solutions ●The technology is mature and stable, and the disposal of hazardous waste reduces the harm to the environment and allows for subsequent resource utilization. ●The disposal process is environmentally friendly, turns waste into treasure, saves energy, has no "three wastes" emissions and meets national environmental requirements. ●Diversified product system, can produce pre-melted calcium aluminate or advantages and economic value.refractory materials such as mullite and other resource products, more industrial ●All materials are utilized, all feeds as well as particles recovered from flue gases during the production process and adsorbents in the filtration unit can be fully utilized and converted into harmless products. ●Low-consumption and low-emission, the whole production process only uses electricity, in line with the national "carbon peak, carbon neutral" clean energy industry requirements. ●Long continuous production period (24-hour continuous production, more than 1,500 hours of continuous stable operation) and short replacement time for related wear parts greatly improve productivity. Advantages of Disposing of Three Wastes and Other Pollutants The generated exhaust gas, wastewater, and waste residue from the hazardous waste disposal process are all treated in a 100% environmentally friendly manner using corresponding enclosed devices. They can be internally recycled for further treatment, with no discharge of "three wastes," achieving industry-leading green factories and processes. Organic pollutants such as dioxins that may be generated during the disposal process can be completely decomposed in the high-temperature melting process. The heavy metals are bonded to the glass matrix, making them difficult to leach, effectively stabilizing the heavy metals. Additionally, the glass matrix is relatively dense, resulting in a significant reduction in volume. Advantages of DC plasma technology The DC plasma technology independently developed by Yi Shun has many advantages compared with the common metal torch plasma technology, such as high power and thermal efficiency, saving electricity and reducing consumption; stable arc light; no eddy current heating phenomenon, avoiding the waste of electric energy; no current skin effect, high conductor utilization, small heat generation, low heat loss, graphite electrode consumption is 30% lower than the consumption of the AC arc furnace, and so on. At the same time, this set of disposal equipment has strong corrosion resistance to corrosive gases; energy saving, easy to operate; low maintenance costs and frequency, high production efficiency;reduce the secondary pollution of the flue gas, heat loss reduction, thermal efficiency and more product advantages. Fly ash disposal Resource utilization Landfilling or resource utilization of domestic waste incineration fly ash is another important issue facing society, and China's Environmental Protection Administration has designated domestic waste incineration fly ash as hazardous waste, and in the process of solving the disposal of fly ash, it is necessary to find the best balance between economic cost and environmental protection. Attempts have been made at home and abroad to dispose of heavy metals before landfilling or resource utilization, and subsequent resource utilization of fly ash. YiShun's patented plasma disposal technology is highly efficient and advanced for the disposal of waste incineration power plant fly ash containing large amounts of heavy metals and dioxins. This process is a method of preparing microcrystalline glass by plasma melting of waste incineration fly ash. Firstly, the fly ash is changed into a mixture by carrying out multiple processing links such as washing and compounding, and then it is sent into a plasma melting furnace for melting treatment, and finally, the hydrous vitreous body slag is obtained. The whole set of production process, the fly ash can be harmless, reduced disposal, maximum effective resource utilization. The finished molten slag can be used as paving material after water quenching, and can be made into high-level decorative material (microcrystalline glass) after deep processing, which can really improve the added value. Zhonghuan International and Yishun have always been committed to the research, development, information consulting and promotion of solid waste disposal related technologies, focusing on the world's ecological energy frontier technology, learning from the global engineering advanced experience, and continuing to deepen the innovation. Through the continuous improvement of the process and technology upgrading, Zhonghuan International and Eshun will surely provide customers with more high-quality and all-around "zero-emission"solutions for plasma melting of hazardous waste.

Contact Us

Contact number

0411-81821250